The Versatility and Advantages of Copper Tubes in Various Applications

Copper tubes have been a staple in the plumbing, heating, cooling, and industrial sectors for decades. With their exceptional properties and numerous advantages, copper tube has become a preferred choice for a wide range of applications. In this article, we will explore the versatility, unique characteristics, and benefits of them.

History and Overview of Copper tubes

Copper has been used by human civilizations for thousands of years, and its application in tubing dates back to ancient times. The advent of modern copper tube manufacturing techniques has further enhanced its usability and popularity. Copper tubes are typically produced through extrusion or drawing processes, resulting in seamless or welded tubes that meet specific industry standards.

Excellent Thermal Conductivity

One of the remarkable properties of copper tubes is their high thermal conductivity. Copper is an excellent conductor of heat, allowing for efficient transfer of thermal energy in various applications. In heating and cooling systems, copper tubes ensure rapid and uniform heat exchange, leading to optimal performance and energy efficiency.

Corrosion Resistance and Longevity

Copper is known for its exceptional resistance to corrosion. Copper tubes can withstand harsh environments, making them suitable for both indoor and outdoor applications. Their resistance to corrosion ensures a longer lifespan compared to other materials, reducing maintenance and replacement costs.

Versatility in Plumbing

Copper tubes have long been the material of choice in copper plumbing tube systems due to their reliability and durability. They are widely used for potable water supply lines, as they do not release harmful substances into the water. Copper’s malleability facilitates easy installation and bending around obstacles, ensuring a leak-free plumbing system.

The application of copper tube in HVAC Systems

Copper tubes are extensively used in heating, ventilation, and air conditioning (HVAC) systems. Their thermal conductivity and corrosion resistance contribute to efficient heat transfer, enhancing the performance of HVAC units. They are commonly employed in refrigerant lines, condensers, and evaporator coils.

Industrial and Electrical Applications

Beyond plumbing and HVAC systems, copper tubes find applications in various industrial sectors. They are widely used in oil refineries, chemical plants, and power generation facilities due to their ability to withstand high temperatures and pressures. Additionally, copper tubes are utilized in electrical wiring systems, as copper is an excellent conductor of electricity.

Environmentally Friendly Choice

Copper is a sustainable material that can be recycled without losing its properties. Recycling copper tubes helps conserve natural resources and reduces the energy required for production. Moreover, copper’s antimicrobial properties make it an ideal choice for applications where cleanliness and hygiene are essential, such as medical facilities.

Methods of Produce Copper tubes and Other Usage

Copper tubes produce by two methods of extrusion and Direct Tube. Due to its vast applications, copper tubes are produced with varied dimensions. Considering the high electrical and thermal conductivity of copper, these copper products are Copper tubes produce by two methods of extrusion and Direct Tube

Other Uses of Copper tube

To satisfy the market demand, copper tubes are produced in three groups of TPC, DHP and DLP with following applications:

TPC: Excellent electrical and thermal conductivity

Applicable to electrical industries specially cable shoe pipes

DHP, DLP: Good workability, drawability, weldability, corrosion and weathering resistance

Good thermal conductivity Applicable to gas and heat exchanger industries

Copper tube sizes

Understanding copper tube sizes is essential for choosing the right tubing for your plumbing, HVAC, electrical, or industrial needs. By familiarizing yourself with the nominal pipe size (NPS) and actual outside diameter (OD) systems, as well as considering various factors, you can make informed decisions when selecting copper tube size that meet your specific requirements. Always consult industry professionals or refer to relevant standards for precise sizing guidelines in your area.

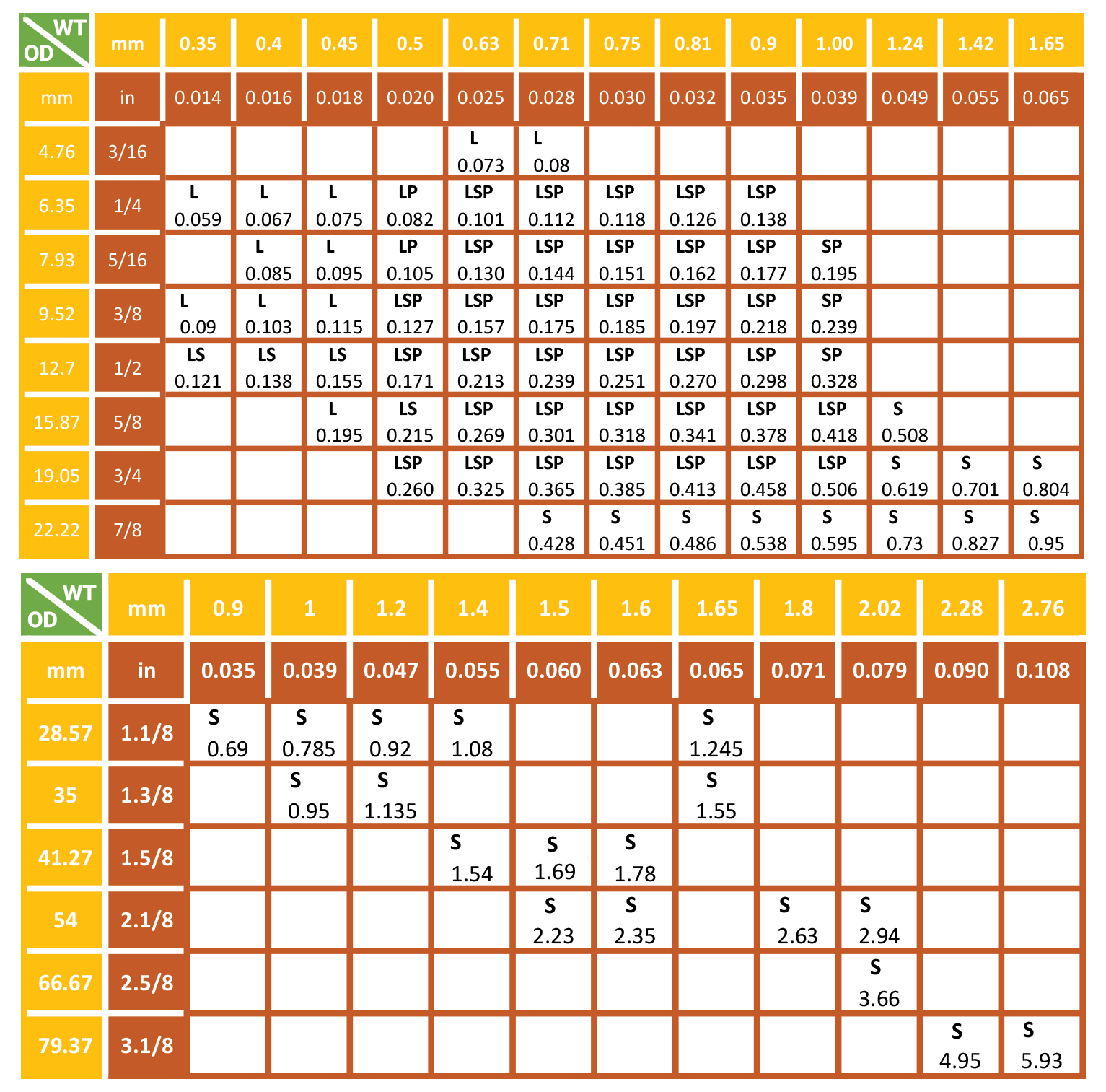

Copper tube size chart

Please note that these dimensions are approximate and may vary slightly depending on the specific copper tube manufacturer and industry standards.